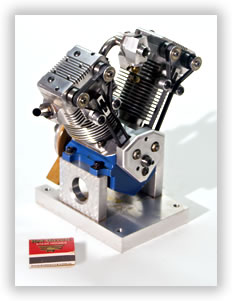

Above: right side view

Below: left side view

|

|

ENGINE NO. TWO DATA

Cylinders: 2

Type: 45º V-Twin, DOHC

Bore: 1.062”

Stroke: 1.125”

Displacement: .995 cu in/cyl x 2 + 1.993

cu in

Compression Ratio: 7.9:1

Ignition: Glow plug

Cooling: Air

Fuel: 15% nitromethane/methanol mix

Max. RPM: 11,000

Est: Horsepower: 2.0

BUILDER'S NOTES

Background -- This engine

was a somewhat similar version of the first DOHC Harley-Davidson

motorcycle engine (the one prior to the current Porsche-designed

model). It doesn't follow the Harley pattern exactly but at

least looks somewhat similar.

Construction -- The

valve train was timing gears and timing belt to the cams.

It was a somewhat difficult engine to make and the results

were OK but not stupendous. It could use more development.

Of course you can say that about almost any one-off engine.

The second one you would make would have some improvements.

This engine crankcase was made in two halves which I made in

pieces which I were welded in place. I then finished them in

the mill. The crankshaft was steel and a bear to make as it

was in three pieces per the Harley system. This consists of

crank throws with tapers to lock into the main journals. I'm

not sure that Harley did this in this engine as I never got

to see the inside of one, but it requires some very close tolerances.

Operation -- This twin ran

OK but used a single model carburetor which was not too flexible.

If I do any more develpment

on this engine I would design and install a couple of slide

valve carbs.

On Castings...

I got interested in making

my own foundry and casting some of the parts for my engines.

It sounded good but I soon realized tha if I were to only make

one unit I might as well go directly to the billet and hog the

parts out from scratch. After all, with castings you have to

make patterns, get them to cast properly, and still machine them.

I finally decided to eliminate the casting process, since I only

make one of each engine. The foundry worked well but was not

much of a solution to making small engines, one at a time. I

spent time later in making fixtures which gave me two more axes

in my mill. I call it MDC or "manual digital control".

|

|

Detail of carburetor

and camshaft drivetrain.

ENGINE DETAIL PAGE LINKS

(click on buttons)

|